Manufacturing Geotextile Fabric: Applications, Features, and Process

Introduction:

Geotextile fabric, a crucial component of geosynthetics, plays a pivotal role in various civil engineering and construction projects. In this guide, we'll explore the uses, features, manufacturing process, applications, and suppliers of geotextile fabric in India, with a focus on Ahmedabad.

Uses:

Geotextile fabric finds extensive application in civil engineering and construction projects for:

- Soil Stabilization: Prevents soil erosion and improves soil stability in embankments, slopes, and retaining walls.

- Drainage: Facilitates water drainage while preventing soil clogging in roads, landfills, and drainage systems.

- Filtration: Separates fine soil particles from drainage materials, ensuring long-term performance of infrastructure.

- Reinforcement: Provides reinforcement in areas prone to soil settlement, such as under roadways, railway tracks, and airport runways.

- Erosion Control: Protects embankments, shorelines, and riverbanks from erosion caused by water flow.

Manufacturing Process:

The manufacturing process of geotextile fabric involves the following steps:

- Polymer Selection: High-quality polymers such as polypropylene (PP) or polyester (PET) are selected for fabric production.

- Extrusion: The selected polymer is melted and extruded into continuous filaments through spinnerets to form yarns.

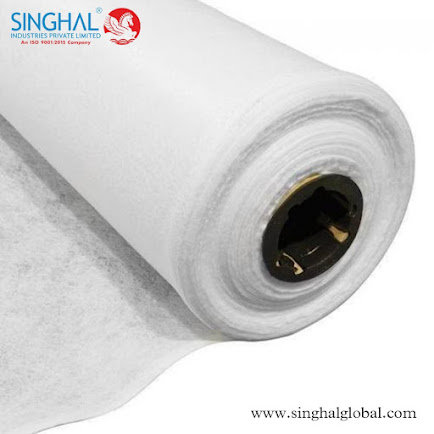

- Weaving or Nonwoven Formation: Yarns are either woven into a fabric on looms or processed into nonwoven fabric through techniques like needle-punching or thermal bonding.

- Finishing: The fabric may undergo treatments for UV stabilization, flame retardancy, or other desired properties.

- Rolling and Packaging: Finished geotextile fabric is rolled onto spools or folded into bundles and packaged for distribution.

Features:

Geotextile fabric offers several features crucial for civil engineering applications:

- High Tensile Strength: Provides robust reinforcement and support to soil structures and retains its strength under various load conditions.

- Permeability: Allows water to flow through the fabric while preventing soil particles from migrating, ensuring effective drainage and filtration.

- Chemical Resistance: Resistant to degradation from chemicals present in soil, water, and construction materials, ensuring long-term durability.

- UV Stability: Exhibits excellent resistance to ultraviolet (UV) degradation, maintaining performance in outdoor environments.

- Customization: Available in various thicknesses, strengths, and permeabilities to suit specific project requirements.

Geotextile Fabric Manufacturers in India:

India hosts several manufacturers specializing in the production of geotextile fabric, catering to the country's infrastructure and construction needs. Singhal Global - a leading Geotextile Fabric Manufacturers in India adhere to stringent quality standards and utilize advanced technologies to produce high-quality geotextile products.

Geosynthetics Products Manufacturers in Ahmedabad:

Ahmedabad, a prominent industrial city in India, is home to numerous manufacturers producing geosynthetics products, including geotextile fabric. Geosynthetics Products Manufacturers in Ahmedabad offer a diverse range of geosynthetic solutions for infrastructure, construction, and environmental applications.

Geotextile Fabric Near Me:

Geotextile Fabric Near Me, consider searching online directories, contacting local construction material suppliers, or reaching out to geosynthetics associations for recommendations. Additionally, manufacturers often have distribution networks or sales representatives to assist with product inquiries and purchases.

Conclusion:

Geotextile fabric serves as a versatile solution in civil engineering and construction projects, offering critical functions such as soil stabilization, drainage, filtration, reinforcement, and erosion control. With its robust manufacturing process, diverse applications, and widespread availability, geotextile fabric continues to contribute significantly to the development of sustainable infrastructure and environmental protection initiatives.

FAQ:

Q: Can geotextile fabric be manufactured using recycled materials?

A: Yes, some manufacturers offer geotextile fabric made from recycled polymers or post-consumer plastics, contributing to sustainability efforts in the construction industry.

Q: What are the key factors to consider when selecting geotextile fabric for a project?

A: Factors such as project requirements, soil conditions, hydraulic properties, durability, and compliance with relevant standards should be considered when selecting geotextile fabric.

Q: Is geotextile fabric suitable for use in coastal erosion control projects?

A: Yes, geotextile fabric is commonly used in coastal erosion control projects to stabilize shorelines, prevent soil erosion, and protect coastal infrastructure from wave action and tidal forces.

Q: Are there regulations or standards governing the use of geotextile fabric in construction projects?

A: Yes, various national and international standards, such as ASTM, ISO, and EN standards, provide guidelines for the selection, testing, and installation of geotextile fabric in construction applications.

Q: Can geotextile fabric be used for environmental remediation projects?

A: Yes, geotextile fabric is used in environmental remediation projects for applications such as landfill capping, groundwater protection, and soil containment, providing effective solutions for environmental protection and restoration.

.png)

Comments

Post a Comment