The Comprehensive Guide to HDPE Ground Protection by Singhal Industries Pvt Ltd

Introduction

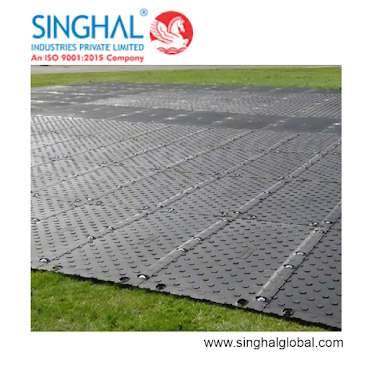

High-Density Polyethylene (HDPE) ground protection solutions are vital in numerous industries, providing robust and reliable surfaces that protect the ground from heavy equipment, vehicles, and foot traffic. These mats are essential for construction sites, outdoor events, and temporary roadways, ensuring safety and preventing ground damage. Singhal Industries Pvt Ltd, a leading manufacturer, offers high-quality HDPE ground protection mats designed to meet diverse needs. This article explores the characteristics, benefits, applications, and considerations for using HDPE ground protection mats.

Understanding HDPE Ground Protection Mats

HDPE ground protection mats are engineered from high-density polyethylene, a material known for its strength, durability, and resistance to environmental factors. These mats are designed to create stable and secure surfaces over soft or uneven ground, distributing weight evenly and minimizing ground disturbance.

Manufacturing Process

The production of HDPE ground protection mats involves several critical steps:

- Material Selection: High-quality HDPE granules are chosen for their superior properties.

- Extrusion: The HDPE granules are melted and extruded into large sheets or panels.

- Molding: The sheets are molded into the desired shapes and sizes, incorporating features like textured surfaces for traction.

- Finishing: Edges are trimmed, and any additional features, such as connectors, are added.

- Quality Control: Each mat undergoes rigorous testing to ensure it meets the required strength, durability, and performance standards.

Applications of HDPE Ground Protection Mats

HDPE ground protection mats are versatile and widely used in various industries:

- Construction Sites: Creating temporary access roads, work platforms, and crane pads, ensuring stable footing for heavy machinery and vehicles.

- Outdoor Events: Protecting lawns, parks, and stadiums from damage during concerts, festivals, and sports events, while providing safe and stable walkways for attendees.

- Utilities and Infrastructure: Facilitating access to remote or environmentally sensitive areas for pipeline installation, maintenance, and electrical grid repairs.

- Military and Defense: Used in training grounds, temporary bases, and disaster response operations to establish secure surfaces in challenging terrains.

- Environmental Protection: Minimizing the impact on natural landscapes, wetlands, and protected areas during construction and maintenance activities.

Benefits of Using HDPE Ground Protection Mats

- Durability: HDPE mats are highly durable, capable of withstanding heavy loads and harsh environmental conditions.

- Strength and Stability: These mats provide a stable surface, preventing vehicles and equipment from sinking or getting stuck in soft ground.

- Ease of Installation: HDPE ground protection mats are lightweight and easy to transport, install, and remove, saving time and labor costs.

- Environmental Protection: By distributing weight evenly and minimizing ground disturbance, HDPE mats help protect the natural environment.

- Reusability: These mats are reusable, providing a cost-effective solution for multiple projects.

- Safety: Textured surfaces offer enhanced traction, reducing the risk of slips and falls.

Innovations and Quality Assurance at Singhal Industries Pvt Ltd

Singhal Industries Pvt Ltd is committed to delivering innovative and high-quality HDPE ground protection solutions:

- Advanced Manufacturing: Utilizing state-of-the-art machinery and techniques to produce mats that meet international standards.

- Sustainable Practices: Embracing eco-friendly manufacturing processes and producing recyclable products.

- Custom Solutions: Offering bespoke solutions to cater to unique customer requirements across different industries.

- Stringent Quality Control: Ensuring every mat undergoes rigorous testing for strength, durability, and performance.

Considerations for Using HDPE Ground Protection Mats

- Site Assessment: Conduct a thorough assessment of the site to determine the appropriate type and number of mats required.

- Installation: Follow proper installation guidelines to ensure the mats are securely connected and laid out to provide optimal stability.

- Maintenance: Regularly inspect the mats for any signs of damage or wear and clean them to maintain performance.

- Environmental Factors: Consider the specific environmental conditions, such as weather and ground type, to choose the right mats for the job.

Leading-Edge Solutions for Surface Protection

HDPE Ground Protection Manufacturer focus on producing durable, high-quality mats designed to protect various surfaces from heavy machinery, foot traffic, and environmental wear. Using high-density polyethylene (HDPE), these mats are engineered for superior strength and flexibility, making them ideal for use in construction sites, event venues, and temporary roadways. HDPE ground protection mats are designed to withstand harsh conditions and provide stable, non-slip surfaces, ensuring safety and efficiency in demanding environments. Manufacturers offer a range of sizes and thicknesses to meet diverse application needs.

Supplying Robust Protection Worldwide

HDPE Ground Mats Exporter specialize in the global distribution of high-density polyethylene mats used for ground protection in various industries. These mats provide essential support and protection for surfaces impacted by heavy equipment, vehicles, and foot traffic. Exporters ensure that their HDPE ground mats meet international quality standards, offering durability, flexibility, and easy installation. By providing reliable shipping and customer support, exporters deliver robust ground protection solutions to clients worldwide, helping to maintain the integrity of surfaces in construction, landscaping, and event management projects.

Essential for Surface Stability and Safety

HDPE Ground Protection Mats are vital for safeguarding surfaces against damage and ensuring stability in high-traffic areas. Made from high-density polyethylene, these mats offer exceptional strength and resilience, capable of supporting heavy loads while preventing soil compaction and erosion. They are commonly used in construction sites, outdoor events, and agricultural applications to create temporary roadways, walkways, and staging areas. HDPE ground protection mats are designed for easy deployment and removal, providing a practical and efficient solution for protecting sensitive ground surfaces and enhancing operational safety.

Conclusion

HDPE ground protection mats are essential tools for ensuring safe and stable surfaces in various applications, from construction sites and outdoor events to utilities and environmental protection projects. Their durability, strength, and versatility make them an invaluable asset in protecting both the ground and equipment. Singhal Industries Pvt Ltd stands out as a leading manufacturer, offering high-quality HDPE ground protection mats designed to meet diverse needs. By focusing on innovation, sustainability, and quality, Singhal Industries Pvt Ltd continues to set the standard in the HDPE ground protection industry.

FAQs

- What are the primary uses of HDPE ground protection mats?

- HDPE ground protection mats are used in construction sites, outdoor events, utilities, military operations, and environmental protection to create stable and secure surfaces.

- How do HDPE ground protection mats compare to traditional ground protection methods?

- HDPE mats offer superior durability, strength, and ease of installation compared to traditional methods like plywood or metal plates.

- Are HDPE ground protection mats environmentally friendly?

- Yes, HDPE mats are recyclable and help minimize ground disturbance, contributing to environmentally friendly practices.

- Can HDPE ground protection mats be customized?

- Yes, Singhal Industries Pvt Ltd offers custom solutions to meet specific project requirements, including size, shape, and additional features.

- What maintenance is required for HDPE ground protection mats?

- Regular inspection for damage, cleaning, and proper storage when not in use are recommended to maintain the performance and longevity of HDPE ground protection mats.

.png)

Comments

Post a Comment